Buty Nike z recyklingu: Styl, ekologia i przyszłość sportu

Odkryj buty Nike z recyklingu! Poznaj inicjatywę Move to Zero, innowacyjne materiały i ekologiczne modele. Sprawdź, jak styl łączy się z troską o planetę.

Eryk Rutkowski

27 listopada 2025

Odkryj buty Nike z recyklingu! Poznaj inicjatywę Move to Zero, innowacyjne materiały i ekologiczne modele. Sprawdź, jak styl łączy się z troską o planetę.

Eryk Rutkowski

27 listopada 2025

Gpplast.pl to miejsce, gdzie spotykają się pasjonaci ekologii, aby dzielić się wiedzą i doświadczeniem. Nasz portal, stworzony przez zespół autorów, oferuje rzetelne informacje, aktualności oraz analizy dotyczące ochrony środowiska i innowacyjnych rozwiązań ekologicznych. Znajdziesz tu artykuły na temat najnowszych badań oraz praktyk, które przyczyniają się do lepszego jutra. Zachęcamy do pozostania z nami i odkrywania inspirujących treści, które pomogą Ci zrozumieć, jak każdy z nas może wpłynąć na naszą planetę.

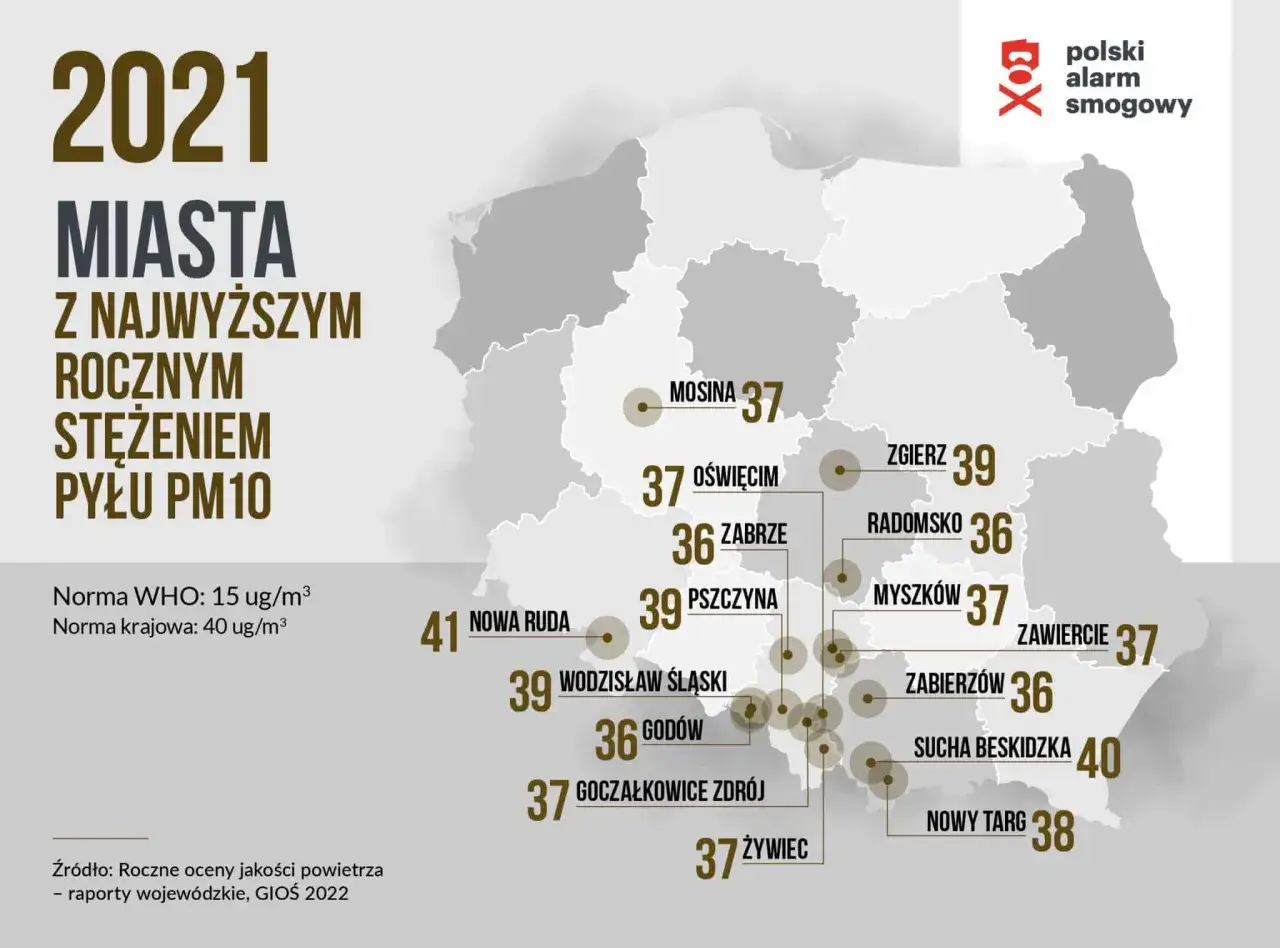

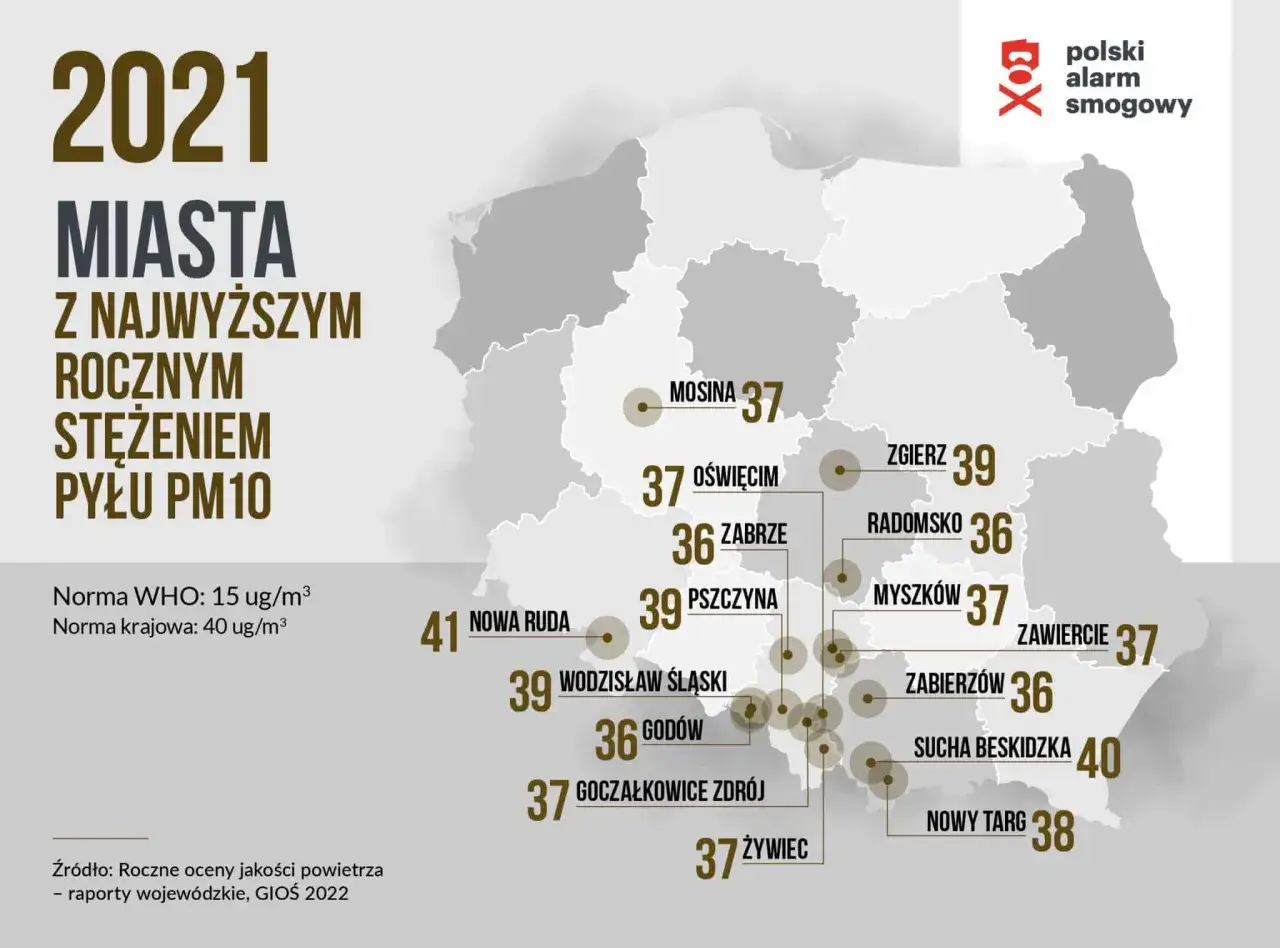

Gdzie jest najbardziej zanieczyszczone powietrze? Poznaj rankingi miast w Polsce i na świecie, przyczyny smogu i jego wpływ na zdrowie. Sprawdź, jak się chronić!

Ktoś pali śmieci? Dowiedz się, gdzie dzwonić (Straż Miejska, Policja), jak zgłosić problem skutecznie i jakie kary grożą sprawcy. Walcz o czyste powietrze!

Gdzie wyrzucić opakowanie po budyniu? Dowiedz się, czy torebka i kubeczek to czarny czy żółty kosz. Rozwiej mity o segregacji!

Mateusz Malinowski

26 listopada 2025

Jak chronić środowisko przed smogiem? Poznaj przyczyny, skutki i skuteczne metody walki od indywidualnych działań po programy państwowe. Sprawdź!

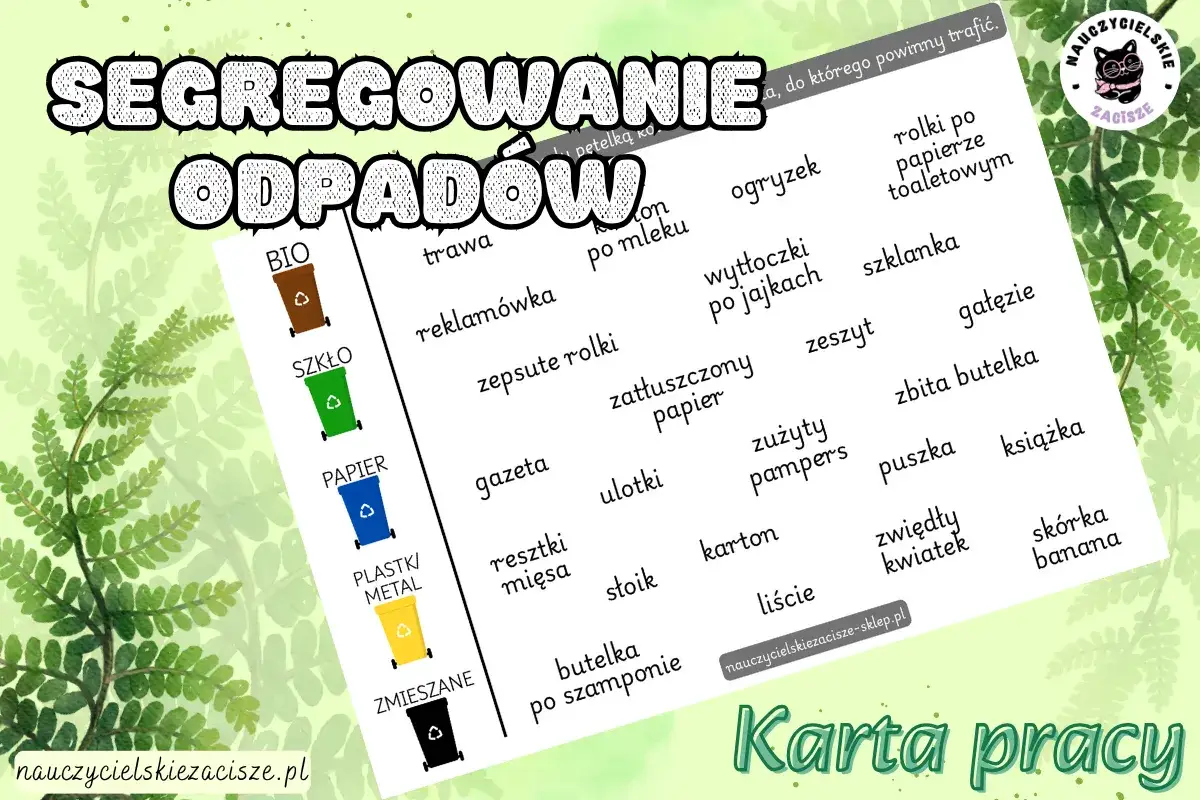

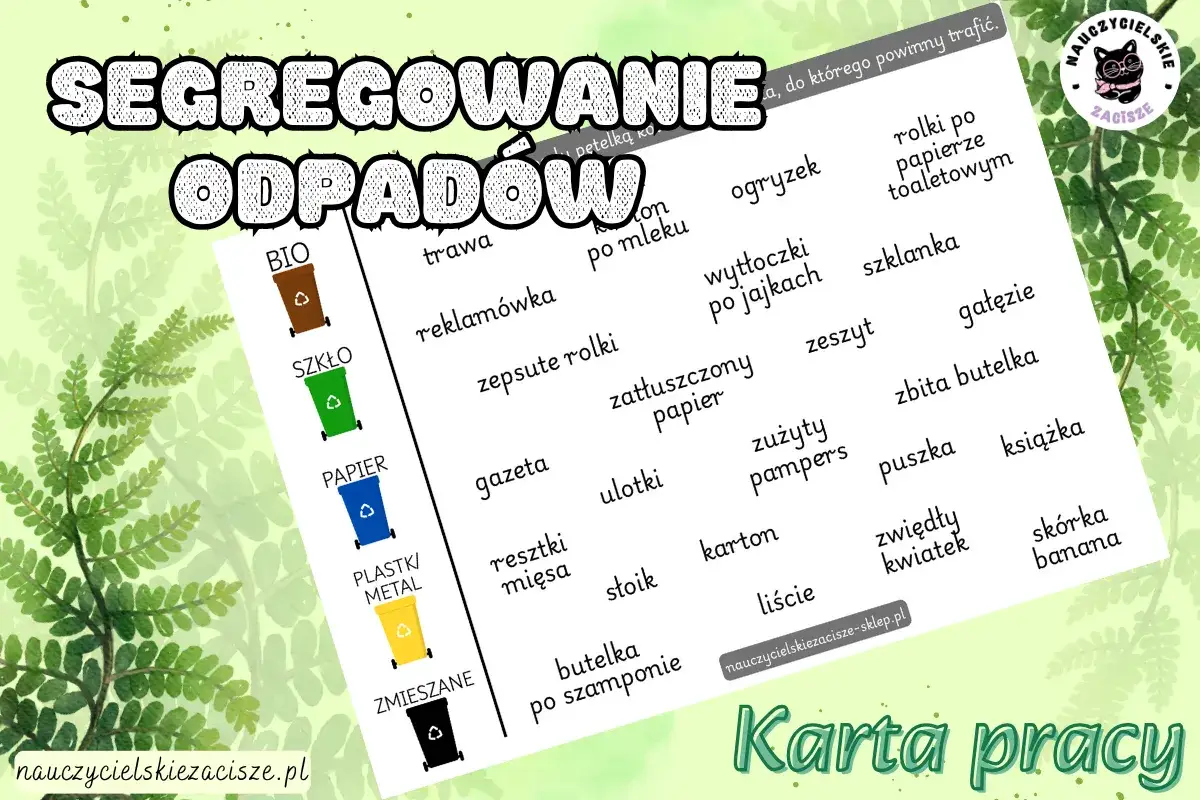

Darmowe karty pracy o recyklingu dla dzieci! Naucz swoje dziecko ekologii przez zabawę. Pobierz materiały i poznaj zasady segregacji w Polsce.

Gdzie jest najbardziej zanieczyszczone powietrze? Poznaj rankingi miast w Polsce i na świecie, przyczyny smogu i jego wpływ na zdrowie. Sprawdź, jak się chronić!

Mateusz Malinowski

27 listopada 2025

Ktoś pali śmieci? Dowiedz się, gdzie dzwonić (Straż Miejska, Policja), jak zgłosić problem skutecznie i jakie kary grożą sprawcy. Walcz o czyste powietrze!

Mateusz Malinowski

26 listopada 2025

Gdzie wyrzucić opakowanie po budyniu? Dowiedz się, czy torebka i kubeczek to czarny czy żółty kosz. Rozwiej mity o segregacji!

Mateusz Malinowski

26 listopada 2025

Jak chronić środowisko przed smogiem? Poznaj przyczyny, skutki i skuteczne metody walki od indywidualnych działań po programy państwowe. Sprawdź!

Arkadiusz Górski

26 listopada 2025

Darmowe karty pracy o recyklingu dla dzieci! Naucz swoje dziecko ekologii przez zabawę. Pobierz materiały i poznaj zasady segregacji w Polsce.

Arkadiusz Górski

26 listopada 2025

Odzysk a recykling: poznaj kluczowe różnice i definicje prawne. Dowiedz się, jak Twoja segregacja wpływa na cele Polski. Sprawdź!

Zmień odpady w skarb! Recykling w ogrodzie to oszczędność, zdrowsza gleba i mniej śmieci. Poznaj proste triki na kompost, upcykling i walkę z chwastami.

Odkryj, jak zrobić coś z niczego! Poznaj praktyczne pomysły na upcykling butelek, makulatury, ubrań. Twórz, oszczędzaj i dbaj o planetę z naszym poradnikiem DIY.

Odkryj świat biżuterii z recyklingu i upcyklingu! Dowiedz się, z czego powstaje, jak ją tworzyć DIY i gdzie znaleźć polskie perełki. Sprawdź, jak zmienia planetę.

Chcesz sprzedać kable do recyklingu? Poznaj ceny, sposoby przygotowania i najlepsze miejsca sprzedaży. Zmaksymalizuj swój zysk!

Ile zapłacisz za śmieci? Stawki, ulgi i kary 2026.

Ile zapłacisz za śmieci? Stawki, ulgi i kary 2026.Opłaty za wywóz śmieci 2026: Zrozum metody naliczania, poznaj maksymalne stawki i kary. Dowiedz się, jak skorzystać z ulg i płacić mniej!

Ucz dzieci segregacji odpadów z angażującymi filmami i zabawami! Odkryj playlistę małego ekologa i praktyczne porady dla rodziców.

Gdynia: Jak segregować śmieci? Kompletny przewodnik po systemie 5 frakcji, nowych zasadach (bio 2025), PSZOK i narzędziach. Unikaj błędów!

Sortowanie śmieci w Polsce: poznaj JSSO, 5 kolorów i gdzie wrzucać problematyczne odpady. Uniknij kar i segreguj świadomie!

Śmieci zmieszane: jaki kolor worka? Czarny! Dowiedz się, co wrzucać, a czego unikać, by segregować poprawnie i nie płacić kar. Sprawdź nasz poradnik!

Pęknięty kubek? Gdzie wyrzucić ceramikę, by nie psuć recyklingu

Pęknięty kubek? Gdzie wyrzucić ceramikę, by nie psuć recyklinguZastanawiasz się, gdzie wyrzucić kubki ceramiczne? Poznaj zasady segregacji ceramiki, uniknij błędów z recyklingiem szkła i sprawdź alternatywy.

Utylizacja płyt CD/DVD Warszawa: Gdzie i jak legalnie wyrzucić?

Utylizacja płyt CD/DVD Warszawa: Gdzie i jak legalnie wyrzucić?Jak prawidłowo utylizować płyty CD/DVD w Warszawie? Poznaj adresy PSZOK i harmonogramy MPSZOK. Dowiedz się, jak segregować opakowania i chronić dane. Sprawdź!

Pieluchy: Gdzie wyrzucić? Prawda o segregacji i eko-mitach

Pieluchy: Gdzie wyrzucić? Prawda o segregacji i eko-mitachGdzie wyrzucić pieluchy? Poznaj zasady segregacji jednorazowych i eko-pieluch. Uniknij błędów i nieprzyjemnych zapachów. Sprawdź, jak dbać o środowisko!

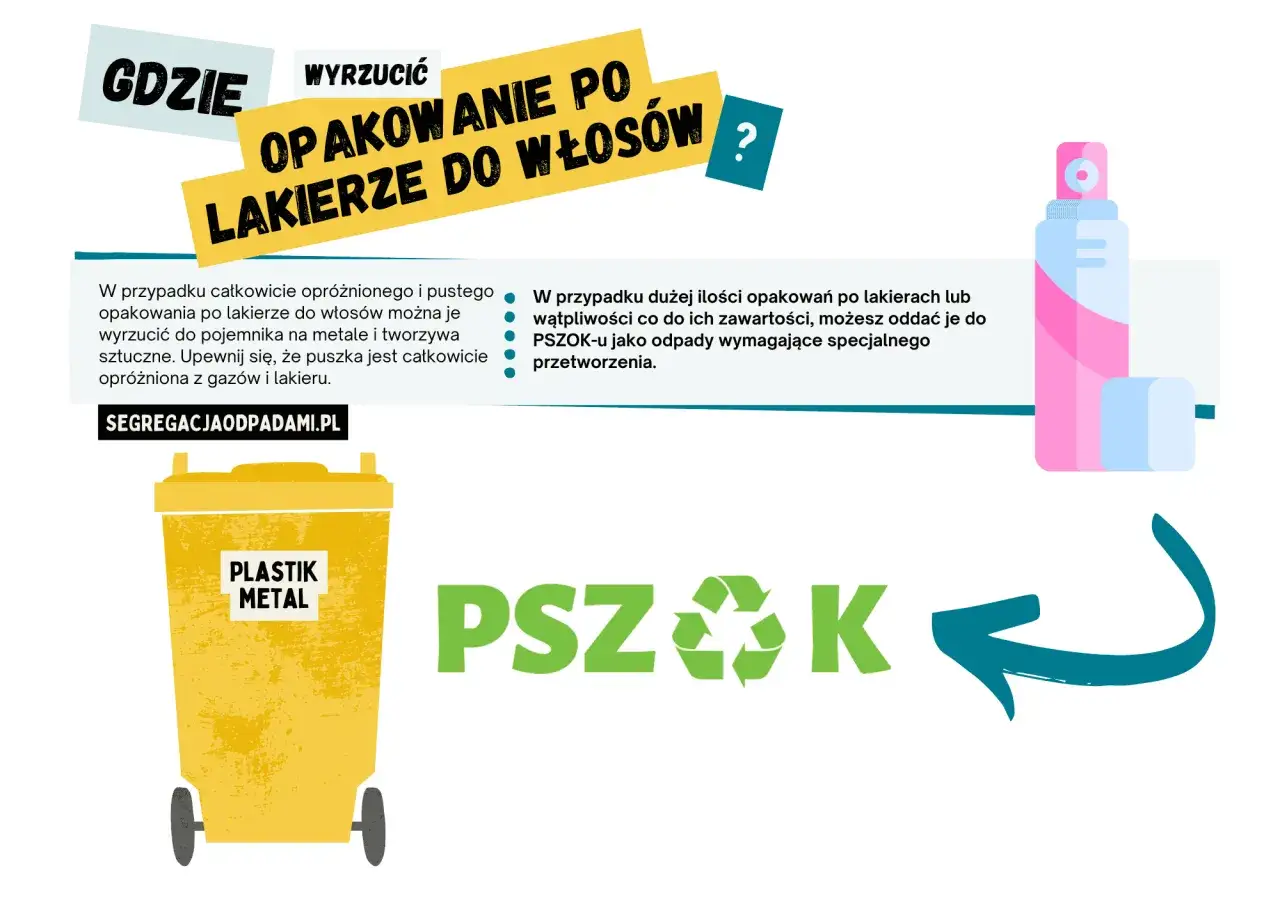

Pianka do włosów: Jak wyrzucić bezpiecznie? Żółty kosz czy PSZOK?

Pianka do włosów: Jak wyrzucić bezpiecznie? Żółty kosz czy PSZOK?Gdzie wyrzucić piankę do włosów? Dowiedz się, czy pusta puszka idzie do żółtego kosza, czy nieopróżniona do PSZOK. Uniknij błędów i segreguj poprawnie!

Znicze: Gdzie wyrzucić? Szkło, wosk, LED jasne zasady

Znicze: Gdzie wyrzucić? Szkło, wosk, LED jasne zasadyGdzie wyrzucić znicze? Poznaj proste zasady segregacji szkła, plastiku, wosku i LED. Uniknij błędów i dbaj o środowisko z naszym przewodnikiem!

Gdzie wyrzucić garnek emaliowany? Nie popełnij tego błędu!

Gdzie wyrzucić garnek emaliowany? Nie popełnij tego błędu!Prawidłowa utylizacja garnka emaliowanego: żółty kosz, PSZOK czy złom? Sprawdź, jak segregować naczynia kuchenne bez błędów!

Oczyszczalnia ścieków dla dzieci: Przygoda brudnej wody!

Oczyszczalnia ścieków dla dzieci: Przygoda brudnej wody!Przygoda brudnej wody! Odkryj z dziećmi, jak oczyszczalnia ścieków zmienia ją w czystą i jak chronić naszą planetę.

Dlaczego w Warszawie jest smog? Niska emisja, auta i pogoda

Dlaczego w Warszawie jest smog? Niska emisja, auta i pogodaCo powoduje smog w Warszawie? Poznaj 3 główne przyczyny: niska emisja, transport i efekt obwarzanka. Sprawdź, co możesz zrobić!